Gateventiler er åbnings- og lukningsenhederne, når der er behov for at starte og stoppe strømmen af væsker eller gasser. They are usually used in plumbing systems which require strength and reliability. In this post, we examine the brass gate valve in detail covering its components, types, advantages, working principles, applikationer, og mere. Så, keep learning!

Indholdsfortegnelse

Skift1) Introducing Brass Gate Valves

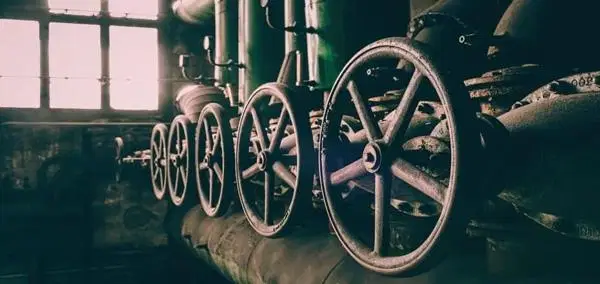

“Brass gate valves allow for the adjustment of fluid flow by raising or lowering a gate(disc) on the inside of the valve body.”

Gate valves have been in circulation for centuries, and they are used to place water systems. They are improved from using wooden components to what are now the brass gate valves that are used today. Such valves have become extremely common within the plumbing schemes in industrial and construction settings.

The corrosion resistance that brass offers allows gate valves to be made from brass to optimize their use in water and chemical applications. Også, copper machining cutting provides excellent durability which allows it to withstand harsh environments for a long time.

Most importantly though, it is cost-effective and allows for the perfect balance on the performance and price for a range of applications.

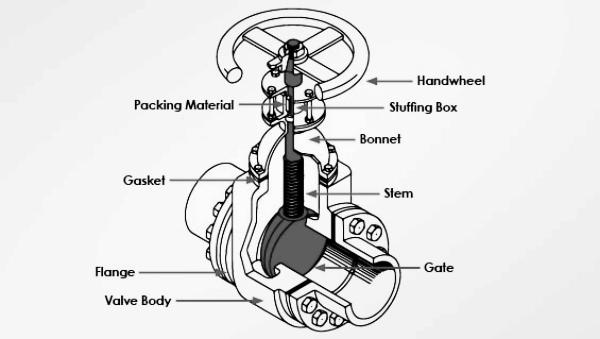

2) Components of a Brass Gate Valve

Knowing the particulars of a brass gate valve can greatly affect the selection of the valve for your systems. Så, let’s see what are those essential components of a brass gate valve;

- Handwheel: Turns the valve by lifting or dropping the gate using the stem.

- Stem: Transfers movement from hand wheel to gate and vice versa for opening and closing

- Gate (Disc): Restricts the fluid movement, and comes in sliding type and wedge type for specific applications.

- Valve Body: Contains the internal parts and the body that holds the valve on the pipeline (flanget, gevind, or weldable joints).

- Bonnet: With bonnet internal components are protected and contained to the valve from leaking.

- Seal and Packing: Seals from leaking and protects from wear and tear to maintain functional operation for a long time.

3) How do Brass Gate Valves work?

Gate valves operate by lifting or lowering a gate or disc located in the center of the valve body with every fluid flow.

- Opening the valve: If the gate is in the elevated position then that allows the full flow of fluid to operate since there is a very low restriction.

- Closing the valve: Lowering the gate now restricts fluid from passing through thus creating a closed seal.

A Gate valve brass does not restrict the full opening and closing but it does minimize fluid friction when in use and ensures a close seal when required. Simply turning the hand wheel will allow spinning of the valve stem which will allow the gate to be raised or lowered as necessary.

Some of the valves will have a visible stem, which will indicate that the valve is operational.

4) Types of Brass Gate Valves

Based on application requirements and processing requirements brass gate valves can be categorized into several types. The six most common types include:

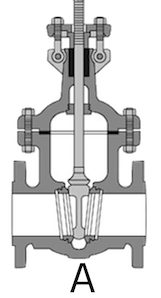

i) Wedge Gate Valves: The wedge gate valve has a V-shape with two surfaces, the wedge angle is usually 2°52′ or 5°. The wedge design allows for better pressure resistance, suitable for high-pressure, high-temperature applications, or enhanced sealing performance situations.

ii) Parallel Gate Valves: Most parallel gate valves have two layers of gates, providing an additional layer of protection. Også, the complex structure makes the double-layer parallel gate valves a higher price.

iii) Outside Screw and Yoke (OS&Y) Portventiler: This type of valve has an open or closed indicator OS&Y which allows seeing its status visibly.

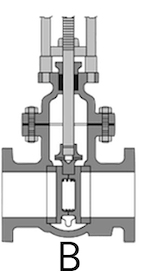

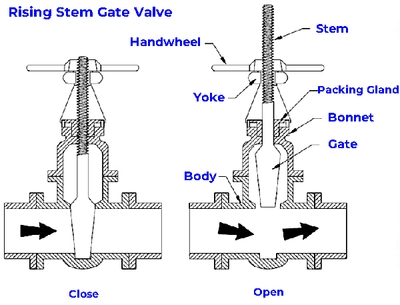

iv) Rising Stem Gate Valves: The valve stem and gate are connected and rise and fall simultaneously. When the hand wheel is turned, the valve stem will rise and exceed the height of the hand wheel. This external structure allows easy lubrication of the stem threads, extending the valve’s service life. Additionally, it visually indicates the valve’s open or closed position, making operation convenient.

v) Non-Rising Stem Gate Valves: Also known as the concealed stem gate valve, the stem nut is located within the valve body and comes into direct contact with the medium. The valve’s opening and closing are controlled by rotating the stem.

The advantages of a non-rising stem gate valve include maintaining a constant height regardless of whether it is open or closed, making it suitable for installations with limited space.

Imidlertid, its disadvantages include the inability to lubricate the stem threads, leading to potential corrosion at the bottom of the stem, which is submerged in the pipeline medium. Additionally, it is not possible to visually determine whether the valve is open or closed.

vi) Specialized Brass Gate Valves: Specific to an industry such as marine or food-grade, these types of valves are specialized.

5) Common Sizes Of Brass Gate Valves

Brass gate valves come in so many sizes which vary with applications. The size of the pipe determines the size of the valve. These sizes are, as a rule, stated in inches like brass gate valve 1/2, 2 inch brass gate valves and others, the most frequent are as follows:

- 1/2 inch and 3/4 tomme: 1/2 brass Gate valve og 3/4 inch brass gate valve are smaller and used in the domestic supply of lines or smaller pipes.

- 1 inch and 1 1/4 tomme: 1 brass gate valves and 1 1/4 brass gate valves catch on better with medium types of systems which are somewhere in between the flow control and strength in leakage.

- Brass gate valve 1 1/2 tomme: 1 1/2 brass gate valves are usually used for small-scale commercial applications. 1 1/2 gate valve brass is common in residential plumbing systems.

- 2″ brass gate valves: Such valves can allow faster instantaneous flows. Brass gate valves 2″ are more regarded in industrial processes or main water lines.

- 3“ brass gate valves and 4″ brass gate valves: 3 inch brass gate valves, og 4 inch brass gate valves are suitable for Heavy-duty industrial and municipal use.

- 6″ brass gate valves: 6-inch brass gate valve is suitable for situations with large flow and high pressure

Here is the corresponding data table for valve sizes and flow rates.

| Gate Valve Size & Flow | |||

|---|---|---|---|

| Størrelse (tomme) | Størrelse (mm) | Flow Coefficient (Kv) | Maximum Flow (m³/h) |

| 1/2″ | DN15 | 5 | 5 |

| 3/4″ | DN20 | 10 | 10 |

| 1″ | DN25 | 16 | 16 |

| 1 1/4″ | DN32 | 25 | 25 |

| 1 1/2″ | DN40 | 40 | 40 |

| 2″ | DN50 | 63 | 63 |

| 2 1/2″ | DN65 | 100 | 100 |

| 3″ | DN80 | 160 | 160 |

| 4″ | DN100 | 250 | 250 |

| 5″ | DN125 | 400 | 400 |

| 6″ | DN150 | 630 | 630 |

The valve features standard inch machining, so it can be adapted to the proper pipe size without problems and permits ease of fitting and functioning. Så, make sure you take into account the specifics of the task and select the appropriate size.

6) Brass Alloy Numbers: Common Brass and Lead-free Brass

Several common brass alloys are employed during the manufacturing process of gate valves. Let’s discuss the most common brass alloy numbers with their to the point description:

- Common Brass Alloys:

| Common Brass Alloy numbers | Beskrivelse |

| CW602N | It conforms to ASTM specifications and is often employed for fittings and services plumbing. |

| CW614N | This alloy grade has met ASTM specifications and can be used for machining and precision parts. |

| CW617N | This brass alloy is also in accordance with the ASTM specifications and is used in applications where the mechanical strength is high. |

- Lead-free Brass Alloys:

Lead-free brass does not put a strain on the environment and is engineered to minimize health and environmental hazards.

| Lead-free Brass Alloy numbers | Beskrivelse |

| C87850 | This is an alloy that is also compliant with the UNI standards and is suitable for applications which demand high performance and durability. |

| CW511L | Conforms to ASTM specifications dated lead-free brass alloy most often employed for green plumbing applications. |

7) Advantages of Brass Gate Valves

Following are a few points due to which brass gate valves excel in different systems:

+ Corrosion Resistance: Brass exhibits excellent corrosion resistance which guarantees durability in hostile atmospheres.

+ Holdbarhed: Withstands high pressure and temperature suitable for both private and industrial sectors.

+ Cost-Effectiveness: Reasonably priced material enabling a fair ratio of cost over performance.

+ Ease of Maintenance: Minimal service/maintenance is needed as the valves are wear-resistant.

+ Versatility: Used in various industries such as plumbing or industrial fluid systems.

8) Ansøgninger

Brass gate valves are widely used in the following fields:

- Residential Plumbing: Ideal for use in controlling water supply in pipe systems and drainage systems.

- Industrial Systems: For use in factories, chemical plants, or oil refineries which require the switching of liquids and gas flow.

- Agricultural and Irrigation Systems: Used in determining the flow of liquid in the irrigation pipeline systems.

- Marine and Offshore: With their property of resisting corrosion, brass makes for great use in marine ships and offshore stations.

- HVAC Systems: Has application for restricting or controlling the circulation of heating and cooling liquid mediums.

9) Installation and Maintenance Tips

Brass gate valves are the best option to use when regulating the flow of fluids within any system. For any device to work properly and remain in operation for a long time, it has to be installed correctly while also being maintained regularly.

Here are some simple tips which can assist an individual or a business install and maintaining their valves in an efficient manner.

- Installation Guidelines

- Prepare the Location of the Installation: Before commencing with valve fitting, one must ensure that the pipes are free from any foreign pollutants and that they are properly aligned to minimize interference during valve fitting and subsequent usage.

- Ensure Proper Torque Adjustment: When utilizing flanged or threaded fittings, it is crucial to ensure that the right amount of torque is exerted. It is vital to apply force neither too excessive as it would compromise the integrity of the valve nor too low ensuring no leakage.

- Ensure Right Orientation of the Valve: One should always adhere to positioning the valve by the determined flow direction. On the majority of valves, there is an arrow that serves the purpose of indicating the correct orientation for flow.

- Preventive Maintenance

! Examine the Equipment: Watch out for rusting, leaking, and tangible gouging to avert issues from worsening.

! Maintain the Valve: Eliminate impurities and accumulation to perform well.

! Provide Lubrication for Parts that Move: Provide lubrication so that sticking occurs and wearing out is reduced.

- Troubleshooting Common Issues

- Repair Installation Problems: Proper alignment and torque should be applied to constructively solve leakage or malfunctioning.

- Repair any Leaks: Check for leaks and tighten or replace seals and packing where necessary.

- Free Stuck Valves: Clean and apply lubrication to valves that do not move o with ease.

- Seal Replacement: Change old seals as fast as possible so that leaking does not happen and functions are maintained.

10) Konklusion

Brass gate valves are essential elements in fluid control systems and deliver high reliability, excellent determination, and low maintenance. Knowing the parts, kinds, and benefits of these valves is beneficial to you if you are a homeowner, or plumbing specialist as they can assist you in your endeavor.

Given their high corrosion resistance and durability, brass gate valves represent an economical option for home and industrial applications.

BMAG as a professional valve manufacturer, offers high-quality brass valves at highly competitive prices, ensuring we meet our customers’ needs with the best service. Contact us.

11) FAQs

Q.1 What is a brass gate valve used for?

A brass gate valve is employed in regulating the flow of liquids or gases in a tube as a means to restrict it to a quarter turn shut or open.

Q.2 Which is better brass or bronze gate valves?

Being less costly, the brass gate valves are most preferred as this type has heightened resistance to corrosion and increased longevity.

Q.3 What are the 2 types of gate valves?

Two types of gate valves are wedge gate valves and parallel gate valves.

Q.4 Are brass valves better?

Ja, because brass is effective weldable, easily cast, solid in machining, and cost-effective while proving to be durable.

Q.5 When not to use a gate valve?

Gate valves are not to be applied in cases when flow regulation of any kind is required. Gate valves are designed for fully open or fully closed cases.

Q.6 What are the disadvantages of gate valves?

Gate valves tend to be bulky, which makes them larger than other valves parts which makes them more difficult to install.

Q.7 What is the most commonly used gate valve?

Wedge gate valves are usually the most used as they are the simplest type and can provide a reliable seal.

Q.8 How to open a brass gate valve?

Turn the hand wheel in an anti-clockwise direction to open a brass gate valve.