Nylon Valves – a Better Value Alternative to Traditional Brass Valves.

Metal valves, particularly brass valves, have been the default choice due to their perceived robustness. Сепак, the landscape is changing rapidly with advancements in material science. Businesses are increasingly seeking alternatives that offer comparable or even superior performance in specific applications, often at a more favorable cost point – Nylon Valves.

If you’re evaluating plastic valve solutions, exploring materials beyond standard options is crucial. High-performance engineered plastic valve options, especially those made from modified nylon, are now providing compelling advantages that challenge the dominance of traditional metals.

Содржина

ВклучиWhat Exactly is a Nylon Valve, and What Makes it Different?

A nylon valve or PA valve is a type of plastic valve where the main body is constructed from Polyamide (PA), commonly known as Nylon. Nylon is an engineering thermoplastic celebrated for its excellent balance of mechanical strength, toughness, wear resistance, chemical stability, and electrical insulation properties.

Utilizing nylon in valve manufacturing allows for the creation of plastic valve solutions that can address issues common with metal counterparts, such as corrosion, heavy weight, and higher manufacturing costs.

Nylon valve products, including nylon ball valve types, are widely applied in areas like water treatment, irrigation, and light industrial processes.

What Are the Common Types of Nylon Valves?

Nylon valve products come in various configurations designed to meet diverse fluid control requirements within piping systems. The most common types include the nylon ball valve, favored for quick on/off control of flow paths due to its simple and robust design.

What Are the Advantages of Choosing Nylon Valves Over Brass Valves?

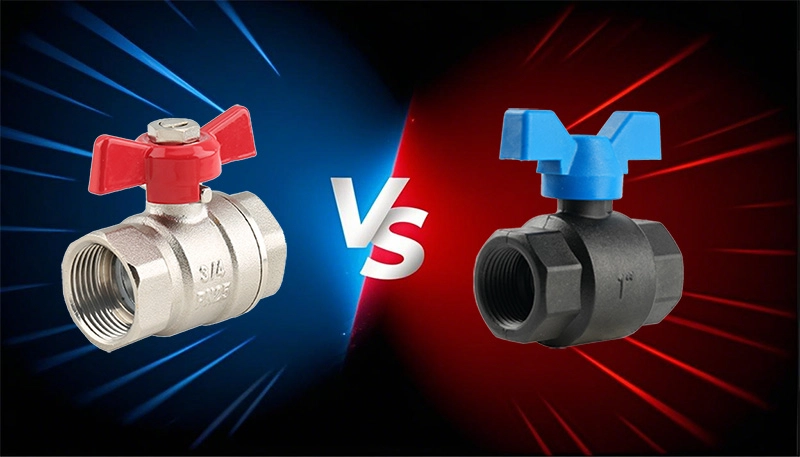

Compared to traditional metal options like brass valves or cast iron valves, nylon valves offer several distinct advantages that can be highly beneficial for many applications.

- Firstly, they boast superior corrosion resistance to water, many acids, bases, and chemicals, making them ideal plastic valve choices for water treatment and chemical processing industries where metal corrosion is a concern.

- Secondly, the lower density of nylon results in lighter valves, simplifying transport and installation while reducing system load.

- Furthermore, due to their insulating material properties, nylon valves are safer than metal valves.

- Crucially, from a business perspective, nylon valves often present significant cost savings in both raw materials and manufacturing processes compared to metal valves.

Are There Any Disadvantages to Nylon Valves?

While offering compelling advantages, standard nylon valves do have potential limitations.

Basic nylon materials generally possess lower mechanical strength and stiffness compared to metals, and under sustained high pressure or temperature, they can be susceptible to creep – a gradual deformation that might affect sealing performance over time.

Their temperature resistance is also lower than that of brass valves, limiting their use in high-temperature applications. Additionally, standard nylon may not be compatible with certain aggressive chemicals. Therefore, selecting a nylon valve requires careful evaluation of the operating environment and material specifications to ensure it meets performance requirements and overcomes these inherent limitations.

What Is The Difference Between Brass Valve And Nylon Valve?

| Feature | Nylon Valve | Brass Valve |

|---|---|---|

| Durability | Tough, wear-resistant, flexible | Strong, rigid, robust |

| Temperature Limits | Lower max temp, narrower range | Higher max temp, wider range |

| Corrosion Resistant | Good chemical/alkali resistance | Corrosion or dezincification in acidic water/seawater |

| Материјал | Пластика (Polyamide) | Metal Alloy (Copper/Zinc) |

| Цена | Lower | Higher |

Which Performance Parameters Are Most Critical When Specifying a Nylon Valve?

For customers specifying nylon valves or any plastic valve, several key performance parameters are paramount to ensuring system reliability and longevity.

The most critical are the maximum working pressure rating (determining the system pressure the valve can safely handle), the operating temperature range (confirming suitability for environmental and fluid temperatures), и media compatibility (ensuring the plastic valve material is resistant to the conveyed fluid).

Other vital factors include flow characteristics (affecting system efficiency), connection type and size (for compatibility with piping), and anticipated lifespan.

Understanding these specifications is essential for correctly matching the valve to the application requirements.

What Makes BMAG Nylon Valve Different?

BMAG Nylon valve products stand apart from many standard nylon valves available on the market, primarily due to our use of high-performance modified nylon material.

A critical component of this material is the incorporation of 30% glass fiber reinforcement. Glass fiber is an exceptional strengthening agent that dramatically improves the tensile strength, flexural strength, stiffness, and creep resistance of the nylon base polymer.

In addition to fiberglass reinforcement, we utilize a proprietary formula to enhance valve performance. This is our secret sauce.

This engineered composite material provides our plastic valves with mechanical performance and stability far exceeding that of valves made from standard, unreinforced nylon.

The Pressure Advantage: How Do We Achieve 20 kg While Others Stop at 10 kg?

Most standard nylon valves, constrained by the inherent properties of unmodified nylon, are typically rated to withstand pressures only up to 10 kg (equivalent to 1.0 MPa). While suitable for many low-pressure applications, this limits their versatility.

Our adoption of modified nylon reinforced with 30% glass fiber and secret sauce fundamentally changes the material’s capabilities. This enhanced composite material exhibits significantly higher strength and rigidity.

This allows us to engineer valve structures capable of withstanding greater stress. Rigorous testing confirms that our modified industrial nylon valves are reliably rated for operation at up to 20 kg (2.0 MPa) of pressure – effectively double the capacity of standard plastic valves made from basic nylon. This expanded pressure range makes our valves viable for many applications previously requiring metal valves.

Pushing Boundaries: We’re Actively Developing Industrial Nylon Valves Rated for 30KG

Innovation is at the core of our operations. Recognizing the market’s increasing demand for higher-pressure plastic valve solutions, we are heavily invested in research and development.

Building upon the success of our 20 kg-rated modified nylon platform, we are targeting a next-generation nylon valve with a pressure rating of 30 kg (3.0 MPa).

Achieving this 30 kg rating will position our plastic valve technology to potentially replace metal valves in even more demanding high-pressure environments, offering customers unparalleled performance and cost benefits in the plastic valve market.

More Durable, Longer Lifespan: How Modified Nylon Enhances Reliability?

The combination of modified nylon and 30% glass fiber reinforcement increases the dynamic performance and long-term reliability of our valves. The glass fibers minimize material creep, ensuring dimensional stability even under continuous load.

The modified formulation enhances wear resistance and fatigue strength, reducing degradation of seats and seals from frequent operation or media flow. Furthermore, our material undergoes special treatment processes to improve its environmental resistance and anti-aging properties.

Collectively, these factors mean our modified nylon valves are inherently more durable and offer a significantly longer lifespan compared to standard nylon valves, translating directly into reduced costs for our B2B clients.

Major Cost Savings: Why Nylon Valves Are 30-40% Cheaper Than Brass Valves?

Cost-effectiveness is a critical factor for B2B procurement decisions.

Developed through extensive experimental research, our modified material significantly enhances valve performance. Сепак, through optimized production management, we have effectively controlled costs, resulting in our high-performance nylon valves being priced30% lower than comparable brass valves.

This significant saving stems from multiple factors: the raw material cost of modified nylon is considerably lower than brass; the injection molding process for plastics is highly efficient for mass production, presenting lower processing costs compared to metal machining and casting; and the lighter weight reduces transportation expenses.

By leveraging material innovation and efficient manufacturing, we deliver a high-performance plastic valve at a fraction of the cost of traditional metal options.

Which Demanding Applications Are Suitable for Our High-Performance Plastic Valves?

Thanks to their superior pressure rating (20KG+), excellent corrosion resistance, enhanced durability, and substantial cost benefits, our modified industrial nylon valves are well-suited for numerous applications that traditionally might have required metal valves.

Examples include: distribution control within urban water supply networks, high-pressure drip and sprinkler irrigation systems, industrial water treatment and circulation loops, handling of certain acidic or alkaline liquids (subject to specific chemical compatibility checks), swimming pool and water park equipment, and various light industrial process controls.

In these sectors, our plastic valves offer a compelling alternative that balances high performance, сигурност, and economic advantage, making them an ideal plastic water valve choice.

How Do You Select the Right Nylon Valve for Your Specific Needs?

Choosing the most appropriate valve for your project requires careful consideration of several factors.

- Begin by determining your system’s maximum operating pressure and temperature to ensure the valve’s rating is sufficient.

- Identify the fluid medium to confirm material compatibility.

- Consider flow requirements, installation space, connection types, and the desired operational lifespan.

Why Partner With Us for Your Industrial Nylon Valve Needs?

BMAG doesn’t just supply valves. Beyond providing high-quality products, we also offer comprehensive OEM/ODM customization services, backed by stringent quality assurance.

We understand the demands of clients for reliable product performance, cost efficiency, and a dependable supply chain. We are dedicated to leveraging innovation to provide plastic valve solutions that exceed expectations, helping you optimize project costs, enhance system reliability, and gain a competitive edge in your market.

Learn More or Get a Custom Solution – Contact Us Today!

If you are interested in exploring the benefits of our high-performance modified nylon valves or require a customized plastic valve solution for a specific application, please do not hesitate to get in touch. Visit our website or contact us directly via phone or email.