Ngu da̲i xi hño ar tsa̲ válvulas, Mahyoni ga suficientes conocimientos exhaustivos pa da nt'ent'i compra razonables.

Ar 'be̲fi adquisición válvulas ar tsa̲ da gi sistemáticamente jar nuya ku̲t'a dimensiones:: Rendimiento técnico, Yá ntsoni ar hño, Control costes, Gestión ar cadena suministro, ne nja ar ciclo ar nzaki completo.

Tabla contenidos

Alternar1. Xingu ne yá nt'ot'e válvulas

1.1 Xingu ya válvulas

- Ar klase ar barbula: barbula bola/barbula compuerta/Barbula njot'i/barbula 'bixt'i, etcetera.

Jar ndu̲i lugar, Gi aclarar ya escenarios ne requisitos njapu'befi. Ya 'befi ja ar barbula ya Honto hñu: Abrir ne cerrar, Ajustar ar caudal, ne nu'bu ar reflujo. Ir nge ya 'na'ño sistemas tuberías, Mahyoni da 'ñets'i 'na'ño válvulas.

Ngu, Ya válvulas bola ya mäs ar za pa tuberías líquidos ne gases tsa da abrir ne cerrar ar rápidamente; Ya válvulas compuerta ya mäs ar za pa líquidos, gas, ne tuberías vapor requieren nkohi flujo ne hingi necesitan abrir da ne cerrar ar xi frecuencia; ne ya válvulas retención ya mäs ar za pa tuberías flujo unidireccional.

Definir ar klase ar barbula ge ar ndu̲i bi thogi pa ta̲i 'nar barbula.

1.2 Parámetros hontho ar barbula

- Diámetro nominal DN: Diámetro nominal ar barbula gi coincidir ko ar tubería; Nu'bu̲ diámetro ya segmentos tubería delantera ne trasera ar inconsistente, mahyoni ga seleccionar ar junta ar casquillo (ar mfats'i ar tubería ar principal ne ar segmento tubería derivación)

- DN15 — DN25: civil hne ngatho

- DN125 — DN50: Njapu'befi industrial convencional

- DN80 — DN150: Nar dätä hño njapu'befi industrial

- DN200 ne superior: Instalaciones ár nt'ot'e ar dehe Nar dätä hño escala

| Tabla conversión tamaño DN barbula ne tamaño pulgada | ||||

|---|---|---|---|---|

| BMAG | ||||

| Hontho generación datos (NPS (Pulgada) |

DN (milímetro) |

Hontho generación datos (NPS (Pulgada) |

DN (milímetro) |

|

| 1/2″ | DN15 | 14″ | DN350 | |

| 3/4″ | DN20 | 16″ | DN400 | |

| 1″ | DN25 | 18″ | DN450 | |

| 1-1/4″ | DN32 | 20″ | DN500 | |

| 1-1/2″ | DN40 | 22″ | DN550 | |

| 2″ | DN50 | 24″ | DN600 | |

| 2-1/2″ | DN65 | 26″ | DN650 | |

| 3″ | DN80 | 28″ | DN700 | |

| 4″ | DN100 | 30″ | DN750 | |

| 5″ | DN125 | 32″ | DN800 | |

| 6″ | DN150 | 36″ | DN900 | |

| 8″ | DN200 | 40″ | DN1000 | |

| 10″ | DN250 | 44″ | DN1100 | |

| 12″ | DN300 | 48″ | DN1200 | |

1.3 Nt'ot'e ár conexión ar barbula

- Barbula conexión brida

Flange connection By bolting two flange plates together to form a sealed joint, suitable for high pressure and high temperature environments. Usually can withstand high pressure (up to 25 MPa or more)

- threaded connection valve

Threaded connection Using the intermesh of threads to connect pipes or equipment, suitable for small diameter pipes and low pressure applications.

Threads according to different national standards are divided into: Metric Thread, Imperial Thread, NPT Thread (National Pipe Thread), BSP thread (British Standard Pipe), JIS thread (Japanese Industrial Standard), G Thread (Gas Thread), ACME thread

Usually suitable for low to moderate pressures (up to 16 MPa)

- butt welded connection valve

Mfats'i soldada tope uniendo ne soldando ya extremos yoho secciones tubería pa formar 'nar conexión xí nze̲di, Tso̲kwa menudo ar gi japu̲'be̲fi jar aplicaciones mextha ar presión ne ar mextha ar mpat'i.

Pe soportar mextha presión (up to 50 MPa)

- Barbula conexión abrazadera

Conexión abrazadera conecta tubería ir nge njapu'befi ar abrazadera, ne ar hei desmontar ne da zeti, ne ar ampliamente utilizado ja ar alimentación, farmacéutico, ne ma 'ra ya industrias.

Nu'bu̲ da nthe̲hu̲ 'ra adecuado pa presiones bajas ma moderadas (up to 10 MPa)

Ar nt'ot'e conexión adecuado ar tsa̲ da seleccionar ir nge ar presión ar sellado requerido.

1.4 Nt'ot'e ár apertura ar barbula

Ya nt'ot'e instalación ne apertura válvulas ar dividen jar:: Barbula manual, Barbula eléctrica, barbula neumática, Barbula hidráulica.

- Ar manual barbula ge ar barbula mäs utilizada da la actualidad, Ar barbula manual hne ngatho pe̲ts'i 'nar klase ar hmihi ne 'nar klase ar volante rueda. Mfädi pa mäs xingu ya sistemas tuberías.

- Ya válvulas eléctricas ya mäs ar za pa sistemas ar control automatizados komongu ar HVAC, Líneas producción productos químicos, ne escenarios válvulas da requieren control remoto

- Ya válvulas neumáticas ya mäs ar za pa líneas montaje fábricas, Brazos robóticos, Equipos transporte ne pulverización gas

- Ar barbula hidráulica ar adecuada pa maquinaria pesada ne equipos ingeniería jar productos químicos, Xí nzi, ne ya industrias aeroespaciales

2. Ya parámetros rendimiento ar barbula

- 'Mui presión ar barbula: PN (Presión nominal, ngu PN16), Nsa̲di (Estándar ar EE. UU., ngu nsa̲di 150).

Indicador: Presión máxima ar 'be̲fi (hne ej. PN16=16 bar).

- Rango mpat'i funcionamiento ar barbula: -50°C ~ 200 °C (convencional), -196°C ~ 800 °C (Nkohi hontho 'be̲fi).

Índice: Resistencia ar mpat'i ar hñei ar sellado (como EPDM ≤120 °C).

- Coeficiente caudal ar barbula: Hmädi Cv yá Kv.

- Leakage grade: ANSI Class IV/V/VI, ISO 5208 A/B/C/D.

Indicador: Allowable leakage (such as Class VI ≤0.1 mL/min). - 5.Opening and closing torque: manual valve ≤50 N·m, electric valve ≤500 N·m.

Indicador: Drive matching.

3. Parámetros ar he̲'mi ar barbula

1. He̲'mi ar barbula

- Body material: latón, bronze, lead-free copper, DZR, Carbon steel (WCB), stainless steel (304/316)

Ngu, DZR anti-dezincification brass is a kind of corrosion resistant material, in which the zinc content is an important indicator. - Stem material:

- The ball material of the ball valve

- Sealing material: PTFE, EPDM, NBR, metal hard seal.

- Nut material

2. Ár nt'ot'e ar superficie ar barbula: Niquelado, Recubrimiento epoxi, rociar.

Test methods include: ASTM B117 salt spray test ≥48 hours, paint film impact resistance test, color paint and varnish grid test.

4. Parámetros instalación ar barbula

1. 'Mui instalación ar barbula: horizontal, vertical, inclinar.

Ngu, check valves are installed vertically, and conventional valves are installed horizontally.

2. Requisitos espacio instalación:

pipe spacing and installation position restrictions also have requirements for the size and shape of the valve

3. Requisitos espacio nja:

Reserve the active space of the hand wheel/handle, the active space of the installation and removal tools, and plan the size of the access port.

5. Certificación ne Estándares

1. Certificación producto:

ISO (International), CE/PED (EU), WRAS(UK), WaterMark (Australia), CRN (Canadá), API 6D (Pipeline valve), IAPMO (Asociación ja ya Ximhai nja Ts'ut'ubi Plomería ne Mecánica).

Ngu, the United States, Canadá, and Australia have the most stringent requirements for lead-free valves.

2. Estándares ntsa̲

'nar. API standards

API 598: Standard for testing tightness of valves.

API 600: Design and test standard for gate valves.

API 607: Standard for fire test of valves.

b. ASME standards

ASME B16.34: Standard for the design, manufacture and testing of valves.

ASME B31.3: Standard for the design of chemical pipelines, relating to the application of valves.

c. ISO standards

ISO 5208: Standard for testing the tightness of valves.

ISO 10497: Standard for fire test of valves.

ISO 9001: Quality management system standard for valve manufacturers.

d. EN standard

EN 12266: Standard for testing the tightness of valves for the European market.

EN 161: Performance standard for valves for gas applications.

e. JIS standard

JIS B 2002: Japanese industry standard relating to the testing and performance of valves.

3. Requisitos ar documentación

Parameters: Material Certificate (MTC), inspection report (COC), drawing.

Ngu: Honja gí hñeti ha 'nar certificado WRAS pa válvulas?

6. Parámetros hontho ja ya nkohi 'be̲fi

1. Barbula xí hñets'i'i mpat'i (Barbula anticongelante yá barbula ma ntsa̲ heladas)

In cold areas, antifreeze valves are required. By detecting the ambient temperature, when the temperature is lower than 3 degrees, the liquid in the pipeline will automatically be discharged to prevent the pipeline from freezing and cracking

Specifications: BS 6364 (low temperature valve standard).

2. Barbula mextha presión

Valve body thickness is the key parameter for valve pressure (hne ej. DN50 Class 600≈20 mm).

Specification: Comply with ASME B16.34 (high pressure valve design).

3. Válvulas sanitarias

Sanitary valves are used in pharmaceutical and food production processes, using 304 y 316 stainless steel.

Indicators: Comply with 3-A Sanitary Standards.

7. Análisis costos adquisición válvulas

1. Costo adquisición:

unit price, MOQ (minimum order quantity), payment method (LC/TT), transportation costs determine the direct procurement cost of the valve.

2. Costos explotación:

service life, quality assurance years, installation difficulty, maintenance frequency, maintenance, replacement costs, and inventory costs comprise the operating costs of valves.

3. Riesgo ar cadena suministro:

It is necessary to clarify the supplier’s delivery cycle (convencional 6-12 weeks, expedited 4-6 weeks) and mode of transportation, and stipulate the supplier’s default terms and amount.

8. Requisitos sostenibilidad

1. Ntsoni ambiental

- Parameters: RoHS/REACH (Restriction of Hazardous substances), energy efficiency level.

- Estándar: ISO 14001 (Environmental Management System).

2. Diseño hñets'i'i jar carbono

- Parameters: Material recovery rate (≥90%), lightweight (15% weight reduction compared with traditional design).

9. Evaluación proveedores

- Technical capabilities: investigate the supplier’s OEM/ODM customized design capabilities, non-standard valve processing experience, patent certificates, certification certificates.

- Production capacity: Evaluate the production capacity (daily output, monthly output) and existing orders through the size of the plant, the number of equipment, and the number of workers, and evaluate whether your orders can be delivered in time if you cooperate.

- Quality control capability: What quality inspection equipment does the supplier have (pressure testing instrument, flow testing instrument, leak detector, ultrasonic flaw detector).

- Case study: Investigate whether suppliers have executed orders for similar products of similar size. If you have no experience, you need to pay more attention in cooperation to ensure that every detail of the order product requirements is understood by both parties.

- After-sales service ability: Product warranty period (usually 2-5 ya je̲ya) Quality suppliers can guarantee products for 10 ya je̲ya.

- Packaging requirements: Whether the product packaging meets the requirements of long-distance transportation, such as shipping boxes and pallets

- Sample testing: needs to confirm whether the samples provided by the supplier meet the requirements of material, size, pressure, appearance, etcetera. Continue to communicate with the supplier if any adjustments need to be made after testing

Formulario evaluación proveedores

In the early supplier evaluation, you can score suppliers, sort more suppliers of the same type, and select the best suppliers.

| Factor | weight | Key indicator | acceptance threshold |

|---|---|---|---|

| Technical adaptation | 30% | Cv/Kv value error ≤5% | in line with PID design requirements |

| Quality Compliance | 25% | Leakage level ≤Class VI | API 598 test passed |

| Total Cost of ownership | 20% | TCO below budget 10% | 5 year life cycle cost analysis |

| Supplier reliability | 15% | OTD ≥95% | Audit of historical delivery data |

| Sustainability | 10% | Carbon footprint reduction ≥20% | LCA report |

Evaluación 'yot'e ya licitación wa cotizaciones múltiples proveedores

When placing an order in the later period, when facing several high-quality suppliers, it is difficult to choose, you can also quantitatively evaluate the ability of suppliers according to different indicators, and calculate the most suitable valve suppliers for you.

| Scoring item | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Price | 8 | 5 | 7 |

| Warranty | 10 | 6 | 6 |

| Delivery | 5 | 10 | 8 |

| Payment Method | 5 | 8 | 7 |

| Total Score | 28 | 29 | 28 |

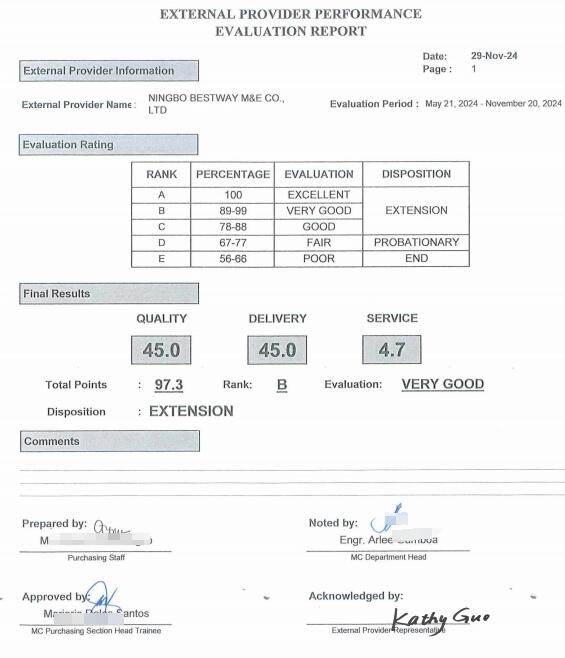

This is a rating sheet for BMAG from our clients.

The above is all the information that a professional valve procurement should know.

Estricto yá ntsoni nä'ä mä ma 'met'o mi, Ár nt'ot'e ar evaluación ítem ya ítem to completamente da 'BATS'I 'nar especialista jar ma̲ha̲ jar 'na̲i xki ingresado ma convertir ar ja 'nar experto ma̲ha̲ jar 'na̲i.

BMAG ngu socio confianza ko 20 ya je̲ya mfeni jar fabricación válvulas mextha ar hño, 'ñent'i da ofrecer excelencia.