ako. Pag-unawa sa Valve Fundamentals: Definitions and Functions

Globe Valves: The Precision Flow Controllers

Globe valves (also known as stop valves) are linear motion valves designed for precise flow control and regulation. Their distinctive feature is a movable disc-type element that moves perpendicular to the fluid flow, enabling accurate flow adjustment. The name “globe” comes from their spherical body shape, though modern designs may vary.

Key Characteristics:

- Linear motion operation

- Excellent throttling capability

- Precise flow control

- Multiple flow path options

- Superior shut-off performance

Mga Check Valve: The Automatic Flow Directors

Suriin ang mga balbula (also known as non-return valves) are automatic valves designed to prevent backflow in piping systems. They allow flow in one direction while automatically preventing reverse flow, operating without external assistance through pressure differential.

Key Functions:

- Automatic operation

- Backflow prevention

- System protection

- One-way flow assurance

- Equipment damage prevention

Major Types and Their Primary Functions

- Types Of Globe Valve:

- Standard globe valves: General flow control

- Angle globe valves: Space-saving installations

- Y-pattern globe valves: Reduced pressure drop

- Needle globe valves: Fine flow control

- Types Of Check Valve:

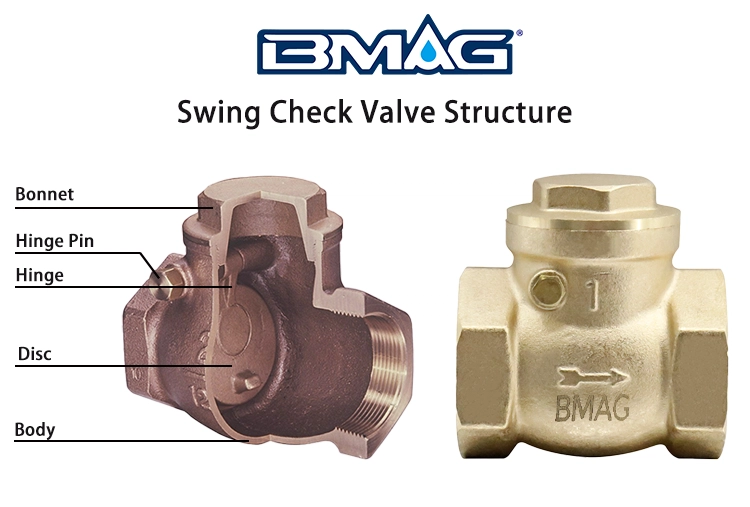

- Swing Check Valve: Traditional design with hinged disc, ideal for horizontal pipelines with clean liquids and gases.

- Inline Check Valve: Compact streamlined design for space-constrained applications with low-pressure drop.

- Stop Check Valve: Combines check valve and stop valve functions for additional system control capability.

- Double Check Valve: Two independent check valves in series for enhanced backflow prevention in critical applications.

- Ball Check Valve: Uses a spherical ball as a closing member, excellent for vertical installations and slurry services.

- Spring Check Valve: Spring-assisted closure for quick response and operation in any orientation.

- Dual Check Valve: This compact double protection device is primarily used in residential and commercial water service.

- Silent Check Valve: Spring-assisted short-stroke design that minimizes water hammer in pump discharge applications.

- Lift Check Valve: Guided disc with vertical movement, suitable for high-pressure and steam applications.

- Dual Plate Check Valve(Butterfly Check Valve): This lightweight, compact design has two semi-circular plates for large-diameter applications and low-pressure systems.

- Y Check Valve: Y-pattern body design offering low-pressure drop in high-pressure steam and process systems.

- Nozzle Check Valve: Integrated nozzle design for critical flow control and high-pressure differential applications.

- Foot Check Valve: Includes integral strainer, typically used at pump suction and well intake applications.

Core Operating Principles

Globe Valves Principle:

- Flow regulation through disc movement

- Throttling capability through stem rotation

- Multiple turn operation

- Positive shut-off design

Check Valves Principle:

- Automatic operation based on flow direction

- Pressure-activated movement

- Self-closing mechanism

- No external power required

II. Cost Efficiency and ROI Analysis: Making Smart Valve Investment Decisions

Cost Reduction Through Strategic Valve Selection

Strategic valve selection is a critical factor in optimizing both initial investment and long-term operational costs. By carefully considering factors such as material selection, sizing, and application requirements, organizations can achieve significant cost savings while maintaining system performance and reliability.

- Initial Investment Optimization

- Proper sizing prevents over-specification and excess costs

- Material selection balancing durability and budget

- Standardization opportunities for bulk purchasing

- Installation cost considerations by valve type

- Operational Cost Savings

- Energy efficiency through reduced pressure drops

- Maintenance cost reduction through proper selection

- Downtime minimization strategies

- Labor cost optimization

- Long-term Value Analysis

- Lifecycle cost comparison

- Durability and replacement frequency

- Spare parts availability and costs

- Service life expectations

ROI Analysis for Different Applications

Return on Investment (ROI) varies significantly across different applications and industries. Understanding the specific benefits and cost savings potential in each sector enables decision-makers to justify investments and quantify the financial impact of proper valve selection.

- Municipal Water Systems

- Investment recovery through:

- Reduced water hammer damage

- Lower maintenance requirements

- Extended system lifespan

- Improved flow efficiency

- Industrial Applications

- Cost benefits through:

- Process optimization

- Equipment protection

- Energy savings

- Reduced product loss

- Commercial Building Systems

- Value generation via:

- Better system protection

- Lower insurance costs

- Reduced maintenance needs

- Extended equipment life

Best Selection Strategies for Different Scenarios

Each application environment presents unique challenges and requirements that demand specific valve solutions. By matching valve characteristics with application demands, organizations can maximize performance while optimizing their investment through targeted selection strategies.

- High-Pressure Applications

- Globe valves for precise control

- Spring-loaded check valves for rapid response

- Silent check valves for pump protection

Investment benefit: 30-40% reduction in pump maintenance costs

- Water Treatment Systems

- Diaphragm check valves for chemical handling

- Dual check valves for contamination prevention

- Ball check valves for vertical installations

ROI factor: Up to 50% reduction in chemical waste

- Building Water Supply

- Swing check valves for main lines

- Globe valves for pressure regulation

- Double check valves for backflow prevention

Cost saving: 25-35% reduction in water damage risks

Cost-Saving Applications

Certain applications offer particularly notable opportunities for cost savings through proper valve implementation. From pump protection to heating system efficiency, understanding these key applications helps identify where the greatest financial benefits can be realized.

- Pump Systems

- Well pump check valves: Prevents drain back

- Compressor check valves: Protects equipment

- Inline check valves: Space-efficient solutions

Average savings: 20-30% on pump maintenance

- Heating Systems

- Hot water check valves

- Water heater check valves

- Silent check valves for circulation

Energy savings: 15-25% through improved efficiency

- Irrigation Systems

- Garden hose check valves

- Drain check valves

- Spring check valves

Water savings: Up to 40% through better control

Risk Mitigation Value

Beyond direct cost savings, proper valve selection plays a crucial role in risk management and compliance. The value of preventing system failures, maintaining regulatory compliance, and protecting equipment often exceeds the initial investment in quality valves.

- System Protection

- Backflow prevention

- Equipment damage prevention

- Process contamination prevention

Risk reduction value: 40-60% decrease in system failures

- Compliance Benefits

- Meeting regulatory requirements

- Reducing liability exposure

- Ensuring safety standards

Compliance cost savings: 30-50% reduction in potential fines

III. Technical Specifications and Selection Criteria

A. Globe Valve Technical Parameters

- Pressure Ratings

- Low Pressure: Class 150 (20 bar)

- Medium Pressure: Class 300-600 (50-100 bar)

- High Pressure: Class 900-2500 (150-420 bar)

- Special Applications: Custom ratings available

- Size Range

- Mini: 1/4″ – 1/2″ (DN8 – DN15)

- Pamantayan: 3/4″ – 24″ (DN20 – DN600)

- Large: 26″ – 48″ (DN650 – DN1200)

- Flow Capacity (Cv) ranges by size

- Materials of Construction

- Body Materials:

- Cast Iron: ASTM A126 Class B

- Carbon Steel: A216 WCB

- Stainless Steel: CF8M/316

- Special Alloys: Monel, Hastelloy

- Trim Materials:

- 316 Stainless Steel

- PTFE

B. Check Valve Technical Specifications

- Check Valve Types and Pressure Ratings

- Swing Check Valves: Up to Class 2500

- Silent Check Valves: Up to Class 900

- Ball Check Valves: Up to Class 600

- Dual Check Valves: Up to Class 300

- Lift Check Valves: Up to Class 2500

- Connection Types

- Flanged (ANSI, DIN, JIS)

- Threaded (NPT, BSP)

- Wafer

- Lug

- Butt Weld

- Socket Weld

- Performance Parameters

- Opening Pressure:

- Pamantayan: 0.5 PSI

- Low Pressure: 0.3 PSI

- Ultra-Low: 0.1 PSI

- Response Time:

- Swing Check: 50-100ms

- Silent Check: 10-30ms

- Spring-Assisted: 20-50ms

C. Application-Specific Technical Requirements

- Water System Applications

- Municipal Water:

- Pressure Rating: Class 150-300

- materyal: Ductile Iron/WCB

- Standards: AWWA, NSF

- Industrial Water:

- Pressure Rating: Class 300-600

- materyal: 316SS/CF8M

- Standards: ASME, API

- Building Services

- Plumbing Check Valves:

- Sukat: 1/2″ – 4″

- Pressure: Up to 150 PSI

- Temperature: Up to 180°F

- HVAC Systems:

- Sukat: 2″ – 24″

- Pressure: Up to 300 PSI

- Temperature: -20°F to 250°F

- Special Applications

- Well Pump Systems:

- Vertical Installation

- Non-Slam Operation

- Self-Cleaning Design

- Hot Water Systems:

- High Temperature Resistance

- Thermal Shock Resistance

- Low Pressure Drop

D. Testing and Certification Standards

- Pressure Testing

- Shell Test: 1.5x Working Pressure

- Seat Test: 1.1x Working Pressure

- Back Seat Test: 1.1x Working Pressure

- Quality Standards

- API 598/6D

- ISO 5208

- EN 12266

- Factory Specific Standards

- Industry Certifications

- NSF/ANSI 61

- ASTM Standards

- CE Marking

- UL/FM Approvals

E. Maintenance Specifications

- Service Intervals

- Regular Inspection: 3-6 months

- Minor Service: Annually

- Major Overhaul: 3-5 years

- Spare Parts Requirements

- Critical Spares List

- Recommended Inventory Levels

- Storage Requirements

- Shelf Life Considerations

IV. Application Solutions and Industry-Specific Implementation

A. Municipal Water Supply Systems

- Water Treatment Plants

- Inlet Control:

- Silent check valves for pump protection

- Globe valves for flow regulation

- Double check valves for backflow prevention

- Chemical Injection:

- Diaphragm check valves for chemical resistance

- Needle globe valves for precise dosing

- Distribution:

- Swing check valves on main lines

- Dual check valves for cross-contamination prevention

Case Study:

The Shanghai Pudong Water Treatment Plant achieved significant improvements by replacing conventional check valves with silent check valves at their pump inlet assembly. This modification resulted in a 30% reduction in equipment maintenance costs and a 25% increase in pump service life through reduced water hammer effects.

- Water Distribution Networks

- Pressure Management:

- Globe valves for zone pressure control

- Multi-spring check valves for surge protection

- Booster Stations:

- Silent check valves for pump discharge

- In-line check valves for space-constrained areas

Case Study:

The London Water District implemented smart globe valves for zone pressure management, resulting in a 30% reduction in water leakage and 25% decrease in energy consumption across their distribution network.

B. Industrial Applications

- Process Water Systems

- High Temperature Applications:

- Hot water check valves (up to 400°F)

- High-pressure globe valves

- Special alloy construction

- Cooling Water Systems:

- Wafer check valves for compact installation

- Butterfly check valves for large diameter lines

Case Study:

The BASF Chemical Plant in Germany resolved their frequent valve replacement issues by implementing special alloy globe and check valves. This upgrade extended valve service life from 8 months to 3 years in their high-temperature processing units.

BMAG offers a variety of Itigil ang Valves and Mga Check Valve that can be customized to meet all customer requirements.

Consult with our professional sales team for inquiries.