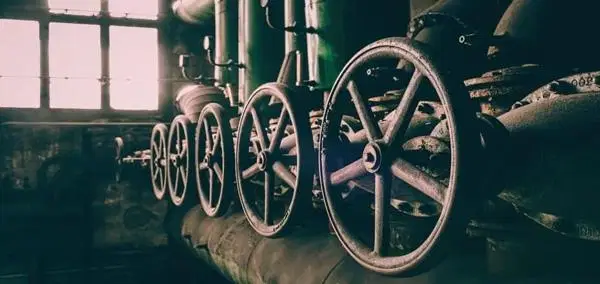

From your house plumbing to huge industrial processes, valves are the unsung heroes of so many systems. These small but crucial devices control the flow of liquids, gases, or mixtures to make our daily lives more comfortable and smooth. But have you ever asked yourself how one tells whether it is a closed or open valve and how they work? Well, this guide will explain everything you need to know about valves, their working, types, and maintenance in an easy so that you never have to ask anyone again. So, let’s dive into it!

Table of Contents

Toggle1) What are valves?

“Valves are like gates and as gates are used to control the number of people passing through, similarly valves control the passage of liquids, gases, and slurries.”

Some valves operate manually via handles or wheels while some use sensors, springs, or some form of electric power to operate. A vital application for them in domestic use would be plumbing where they serve to enable and disable the flow of liquids. Apart from this, they control temperature, pressure, and flow speed in industrial processes.

2) What are the basic structural elements of a valve?

In order to regulate the flow of liquids or gases, a valve has a few basic parts working together within it. A valve usually has the following main parts:

- Body: Position of the body is side-by-side with the pipe and it integrates every internal structure of the valve inside it. This portion of the valve attaches to other parts such as pipes.

- Bonnet: This is the top portion of the valve and it encloses the internal components of the valve. You can take it out for servicing a valve.

- Stem: The stem is a critical portion of the valve since it links up the valve handle and the inner parts of the valve. The inner parts are the parts that are responsible for controlling the fluid.

- Seat: The seat functions as a contact area where the valve closes to stop the flow of fluid.

- Disc or Ball: These are the parts that rotate to close or open the valve. Discs, balls, and gates are all types of this part. Moreover, it depends upon the design of a particular valve.

3) Material used for valves composition

Generally, valves are made from different materials, and you select the material based on the fluid type, pressure, and temperature. Common materials include:

- Stainless Steel: Because of its strength and high resistance to corrosion, stainless steel is extensively used for valves. Stainless steel valves are usually used with water, steam, and chemicals. This is suitable for both domestic and industrial use.

- Brass: This is resistant to corrosion and able to withstand tensile stress. It makes it suitable for plumbing purposes and low-pressure systems.

- Cast Iron: You can use it in larger industrial valves as it has the strength and cost benefits in water and gas systems.

- Bronze: This material is corrosion-resistant. Hence, it is common in boats and when the temperatures are very high.

- Plastic: These valves are lightweight, cheap, and resistant to certain chemicals and pressure. These properties make them useful in low-pressure and non-critical applications.

4) Types of valves

Depending on the structure and function, there are various types of valves available in the market. For your ease, let’s discuss some of the common valve types and how to tell if a valve is open or closed.

i) Ball Valve

The ball valve has a spherical disc in the center. It serves the purpose of flow control of the ball valve. What happens is that the ball turns within the valve body to permit or block the fluid.

- Types:

a) Floating Ball Valve: The ball would ‘float’ between the seats and flow pressure aids it to seal on one of the seats.

b) Trunnion Ball Valve: The seat will move while the ball remains intact in an effort to keep the seal tight. This is often used in high-pressure systems.

- Identifying Open vs. Closed Positions:

Ball valve open or closed? Okay! If both the face plate and the seal valve are vertical while the handle is parallel to the pipe meaning the valve itself is open. In instances, where the handle is perpendicular to the pipe, you can consider ball valve closed.

Operation method:

When you turn the handle of the valve 90 degrees clockwise, the flow is able to pass through since the ball does the exact same movement thus allowing the flow through. Moving it anticlockwise by turning the ball back, means ball valve is closed.

- Applications:

They are common in water supply schemes, and natural gas pipelines for fast shut-off control.

ii) Gate Valve

A gate valve has a wedge-shaped gate that reciprocates about its axis to control the flow of a fluid. The gate slides vertically within the valve body.

- Types:

a) Parallel Gate Valve: The gate is parallel to the seats and is used at low pressure.

b) Wedge Gate Valve: A V-shaped gate can tightly seal against the valve seats. It is commonly used in high-pressure applications.

- Identifying Open vs. Closed Positions:

Water valve open or closed? Okay! When you lift the gate, the valve opens (when the valve is straight with the pipeline). When you lower the gate, the valve closes to seal off the aperture (when the valve is perpendicular to the system).

- Operation method:

Let’s learn gate valve open close direction. The hand wheel is turned anti-clockwise to raise the gate and is turned clockwise in order to lower the gate.

- Applications:

Gate valves are most often used in water and wastewater systems, pipelines, and also oil and gas industries.

iii) Butterfly Valve

A butterfly valve has a circular disc in the middle that rotates to control the flow. You mount the disc on the valve shaft, and the position of the disc shaft determines the valve’s open and close direction.

- Types:

a) Wafer Butterfly Valve: This type is fixed between two flanges. It is compact and lightweight.

b) Lug Butterfly Valve: It has threaded holes for mounting which helps in its installation.

c) Double-flanged Butterfly Valve: It has flanges at both ends. It is suitable for use in bigger systems and areas with greater pressure requirements.

- Identifying Open vs. Closed Positions:

The valve is in the opened position when the disc is in line with the flow. When the disc is in a perpendicular position, the valve is in closed position.

- Operation method:

You can control the valve’s flow by a disc which is able to turn at a 90-degree angle.

- Applications:

owing to their effective space economy, these valves are commonly used in HVAC systems, water treatment facilities, and pipelines.

iv) Check Valve

A check valve consists of a mechanism that enables flow in one direction but automatically prevents it when flow reverses. This feature avoids reverse flow which may lead to pollution of the system.

- Types:

a) Swing Check Valve: This is a type of valve that uses a disc that swings to prevent backflow.

b) Ball Check Valve: A valve in which backflow is prevented by a ball within the valve that moves when there is backflow.

c) Lift Check Valve: In this type of valve, a disc or ball is raised when the direction of flow is right but switches down to prevent any kind of reverse flow.

- Identifying Open vs. Closed Positions:

You can say a valve is open when the disc is away from the lock seal. If the flow changes direction, the valve closes.

- Operation method:

The valve opens and closes automatically in line with the flow direction of the fluid without any manual operations.

- Applications:

It is installed in check valves of water pumps, sewage systems, and oil pipelines to ensure that fluids do not return.

v) Globe Valve

Globe valves also called stop valves have sphere-shaped bodies just like a globe. Inside, a disc compresses the fluid to manage the flow rate within the valve.

- Types:

a) Standard Globe Valve: This is a basic type meant to control the flow for everyday use.

b) Angle Globe Valve: The narrow passage allows the fluids to flow in an angled way thus lowering the resistance.

c) Y-pattern Globe Valve: The valve is shaped like a Y, resulting in a significant reduction in pressure drop. This property makes it applicable to high-pressure spheres.

- Identifying Open vs. Closed Positions:

The valve lifts the disc to open and then pushes the disc downward to close and cut off the supply.

- Operation method:

To open the valve turn the handle wheel clockwise. But, if you want to close it then reverse the movement.

- Applications:

Widely found in air conditioning devices, water filter systems, and in several plants for fluid flow control.

vi) Solenoid Valve

In terms of automation, solenoid valves are quite popular due to their electrically operated features. They have electromagnetic coils to operate a linear solenoid to control a valve.

- Types:

a) Direct-acting Solenoid Valve: This type of valve loses the need for external pressure. You place the solenoid directly in the valve, which opens and shuts the valve.

b) Pilot-operated Solenoid Valve: A valve has a smaller pilot valve that is less active than the first valve. This smaller valve controls the larger valve.

- Identifying Open vs. Closed Positions:

The energizing of the solenoid results in the opening of the valve. In case the solenoid is not energized or de-energized, the valve closes.

- Operation method:

A solenoid valve controls the fluid’s movement by opening or closing in response to an electrical signal. When you close the solenoid valve, fluid does not flow in the system.

- Applications:

Automated systems such as irrigation, HVAC systems, and water treatment plants use it.

vii) Pressure Relief Valve

A pressure relief valve is a device that releases liquid or gas when a specific value of pressure gets surpassed in a system.

- Types:

a) Spring-loaded Pressure Relief Valve: You shut the valve when you lower the pressure. It uses a spring to open the valve when the pressure rises.

b) Pilot-operated Pressure Relief Valve: By doing so, the pilot system helps this type maintain pressure relief valve control.

- Identifying Open vs. Closed Positions:

In normal operation, the pressure maintained in the system does not allow for the valve to open and instead remains closed. If the pressure exceeds the value of the set limit, the valve, contrary to its normal condition, opens.

- Applications:

Such valves can be found in several appliances including boilers, tanks, and even pressure vessels. Yes! It protects them against higher-than-required pressure levels.

5) How to keep your valves up-to-date: Troubleshooting Common Valve Issues

Valves are the components that ensure the full action of a mechanical system, therefore, you should ensure their proper operation. There are, however, some valve issues and their maintenance follows:

? Stuck or jammed valves: Debris, oxidation, or mechanical failure can make some valves stuck. So, these valves require regular maintenance and even cleaning periodically. Alternatively, you can lubricate moving parts or change broken components.

? Leaked/sealed Valves: Seal leakage is a common problem, often caused by badly fitted seals. So, you can replace ruptured seals, and inspect valves regularly for further protection. If seawater leakage persists, it can lead to valve corrosion.

? Increased Flow Rate: This is most often caused by obstructed valve seats or damaged valve seats. Allowing the mechanical valve to disassemble and put back in pieces can be the solution.

So, you got it that you can reduce valve failure with regular maintenance and checking. You know research says that around 40 percent of valve failures are a result of poor valve scheduled maintenance or repairs. So, you will be careful! right?

6) Safety precautions while inspecting Valve Operations

Other than jamming up, valves can be a potential hazard and problem when operating it. So, you should pay attention to the following measures while inspecting a valve operation;

! Shut off the system: First, turn off the system as well as the valves. Then, make sure to depressurize the system to give the pump check and remove any remaining pressure build-up or leak flow.

! Use proper protection: Whenever you are in a hazardous zone, make sure that you have gloves, safety goggles, as well as suitable clothes on.

! Look for leaks: Check the valve and its components for any areas that are leaking. Don’t ignore it! This is a vital step before moving on with the inspection.

! Employ the correct tools: You should employ the correct tools to prevent damaging the valve or causing injuries.

! Observe the guidelines set forth by your manufacturer: It is important to look at the safety precautions and operating procedures defined by the manufacturer of the product.

7) Conclusion

In a nutshell, you can say that valves are usually in the open position when they are parallel to the pipelines. And, they are usually in closed position when they are perpendicular to the pipelines. Apart from this, you are now clear that the valve inspection and servicing schedule should be performed on a routine basis if you want your system to work safely and efficiently.

One important thing to share with you if you are looking for the best quality and high-performance valves then BWValve products are definitely worth considering. The company specializes in a wide selection of professionally made ball valves, gate valves butterfly valves, and others designed to withstand the required performance in many industrial functions.

BW Valve is enabled to design and manufacture product solutions that focus on accuracy and meeting customers’ expectations. So, wait for what? We are just one click away.